1 month ago

Surface Preparation Before Anodizing: How It Impacts Finishing Strength🟧 IntroductionBefore anodizing begins, aluminum undergoes several critical preparation steps that define the strength, uniformity, and appearance of the final oxide layer Learn how proper surface preparation before anodizing influences finish strength, color consistency, and corrosion resistance through advanced cleaning and conditioning stages.

top News

1 month ago

Green Aluminum: The Future of Sustainable Manufacturing

🟧 IntroductionAs global attention shifts toward environmental responsibility, green aluminum has emerged as a leading solution in sustainable manufacturing

Discover how green aluminum, recycling, and low-emission production technologies are shaping the future of sustainable and eco-friendly industry.

2 months ago

How Anodizing Quality Impacts the Reputation of Your Final Project

🟧 IntroductionA project’s appearance isn’t only about design — the quality of finishing is often what defines its reputation

Learn how high-quality anodizing enhances project appearance and market value, and why poor finishing can damage the professional reputation of any architectural or industrial project.

2 months ago

10 Common Mistakes When Buying Aluminum Profiles – and How to Avoid Them

🟧 IntroductionBuying aluminum profiles may seem straightforward, but many engineers and contractors fall into common mistakes that result in project delays, poor performance, or unexpected costs

A practical guide explaining the 10 most common mistakes engineers and contractors make when buying aluminum profiles, and how to avoid them for better quality and reliable supply.

2 months ago

Factory vs. Distributor: What’s the Difference in Aluminum Supply?

🟧 IntroductionThe aluminum market is full of suppliers — factories, distributors, and trading agents

Learn the difference between buying aluminum from a factory versus a distributor, and how direct sourcing guarantees better quality, lower cost, and professional support.

2 months ago

Why Aluminum Has Become the Top Choice for Shower Cabin Design

🟧 IntroductionAs bathroom design evolves toward sleek and functional aesthetics, the materials used must balance elegance, practicality, and durability

Discover why anodized aluminum is the best material for shower cabins — lightweight, moisture-resistant, stylish, and durable for long-term performance.

2 months ago

How to Choose the Right Anodizing Color for Your Project’s Identity

🟧 IntroductionChoosing an anodizing color is more than a visual decision — it’s part of your project’s design identity

Learn how anodizing colors reflect your project’s identity and how to select the perfect shade to match your architectural vision and design aesthetic.

3 months ago

Anodized Aluminum in Modern Interior Design

🟧 IntroductionAnodized aluminum is no longer confined to industrial applications — it has become a statement material in modern interior design

Discover how anodized aluminum elevates modern interior design through its use in kitchens, furniture, and decorative wall partitions – combining elegance with durability.

3 months ago

Controlling Anodic Layer Thickness and Quality According to ISO 7599: A Practical Application Inside the Factory

🟧 IntroductionIn aluminum finishing, visual beauty means nothing without precision

See how Golden East Factory applies ISO 7599 standards to precisely control anodizing layer thickness and ensure consistent quality across production stages.

3 months ago

Post-Anodizing Protective Coatings – The Dual Protection for Aluminum

🟧 IntroductionOnce anodizing is complete, aluminum’s surface transformation isn’t over

Learn about the different types of sealing processes after anodizing and how they improve corrosion resistance, color stability, and surface quality.

3 months ago

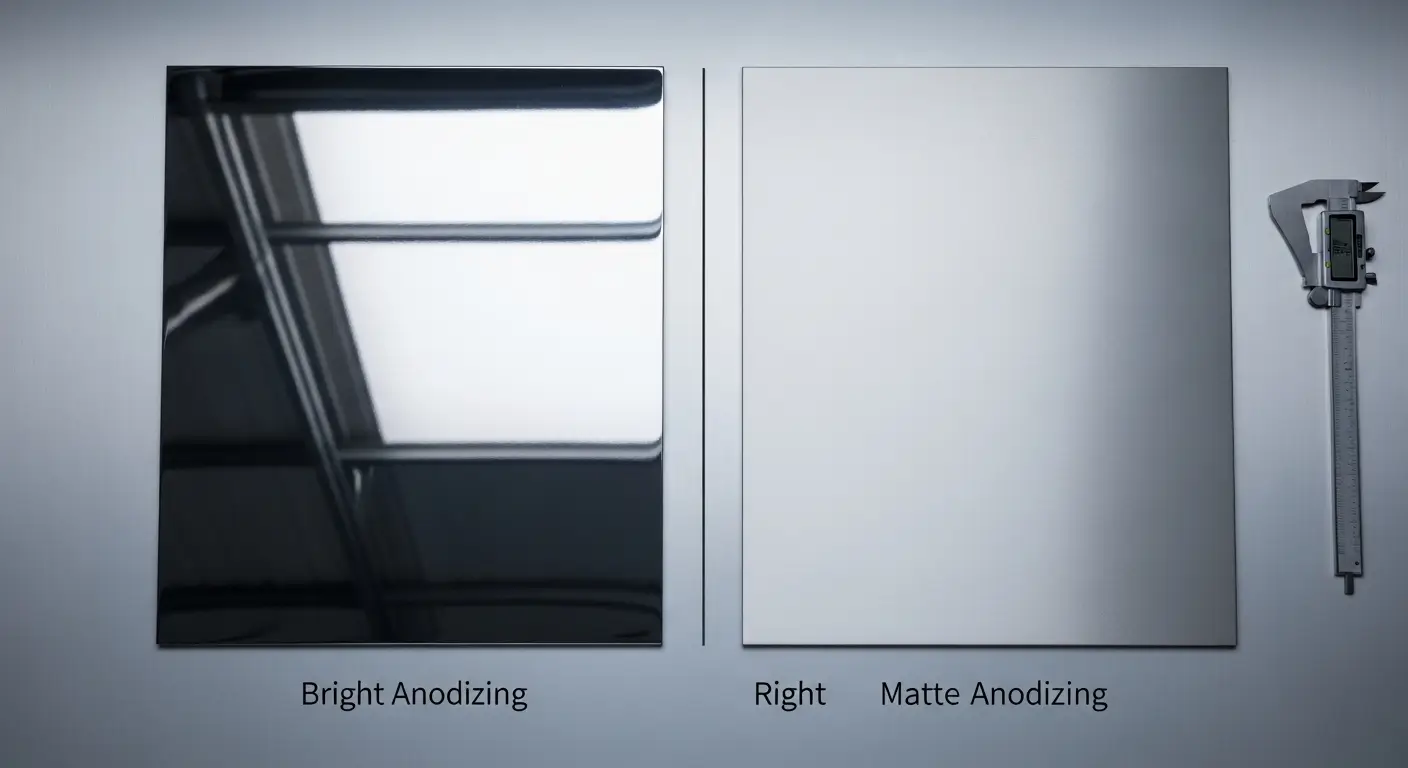

Bright vs. Matte Anodizing: When to Choose Each Finish

🟧 IntroductionAnodizing defines the final look and performance of aluminum surfaces

Discover the key differences between bright and matte anodizing finishes—their appearance, technical properties, and ideal applications for aluminum products.

4 months ago

Electrolysis in Anodizing: The Science Behind Surface Quality

🟧 IntroductionHave you ever wondered how ordinary aluminum becomes shiny, durable, and corrosion-resistant? The secret lies in electrolysis — a fascinating process that uses electricity to trigger chemical reactions, transforming the metal’s surface into a hard, protective oxide layer through anodizing

Discover how the electrochemical process of anodizing transforms aluminum through electrolysis, creating a durable oxide layer that enhances appearance and corrosion resistance.

4 months ago

ISO 7599 – The Global Standard for Aluminium Finishing

The international standard ISO 7599:2018 is the primary reference for specifying decorative and protective anodic oxidation coatings on aluminium and its alloys

Discover how Golden East applies ISO 7599 in aluminium anodizing to ensure European-level quality, corrosion resistance, colour stability, and long-lasting finishes.

7 months ago

Precision in Every Micron: How Quality is Measured in Aluminum Manufacturing

🟧 IntroductionIn aluminum manufacturing, where even microns define product performance and aesthetics, precision measurement is not just a technical step — it's what separates standard products from market leaders

Learn how precision measurement down to the micron ensures the strength, safety, and aesthetic quality of aluminum products across every stage of production.

7 months ago

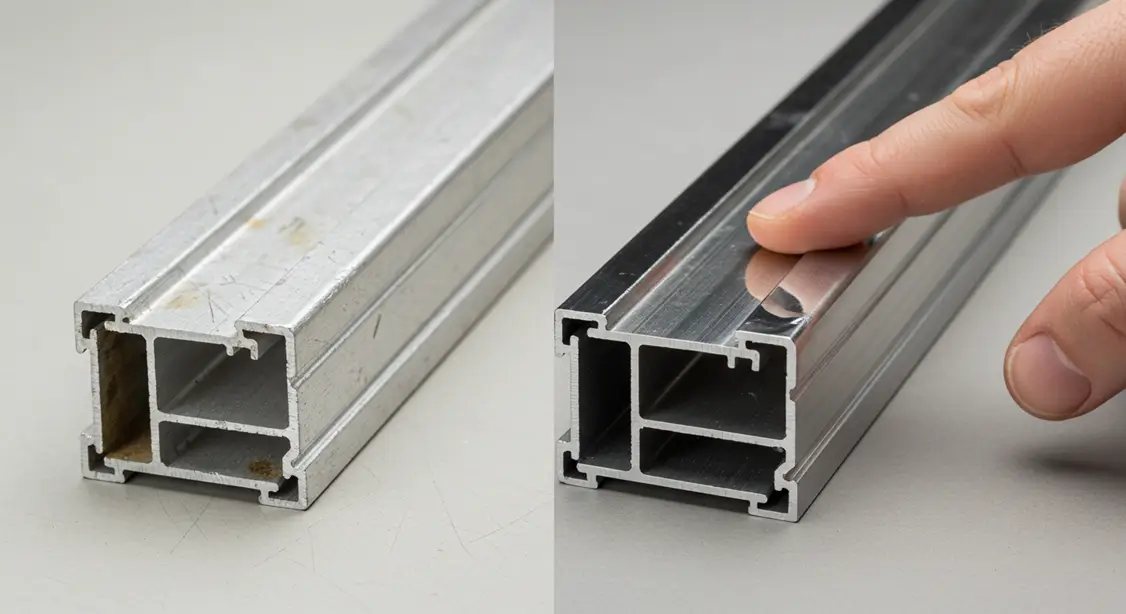

The Difference Between Anodized and Non-Anodized Aluminum

IntroductionAnodizing is a powerful surface treatment that enhances the performance and aesthetics of aluminum

EN: Discover the difference between anodized and non-anodized aluminum in terms of durability, appearance, and protection. Learn why anodizing is essential at Golden East Factory.

9 months ago

Color Control in Anodizing and Its Aesthetic Applications

Introduction: Anodizing enhances both durability and appearance

Learn how anodizing allows precise color control in aluminum finishing, and discover its impact on product design in industries like architecture and consumer electronics.

9 months ago

The Role of Anodizing in Modern Architectural Design

Introduction Anodizing has become an essential design tool in contemporary architecture, especially for building facades and structural aluminum elements

EN: Explore how anodized aluminum transforms building aesthetics with durability, color flexibility, and sleek finishes in modern architecture.

9 months ago

Anodizing vs. Traditional Metal Coating: What’s the Difference

Introduction: Industries are increasingly adopting anodizing over conventional coatings due to its superior durability and environmental safety

Compare anodizing with painting, powder coating, and plating. Understand the advantages of anodizing in terms of durability, appearance, and eco-friendliness.

9 months ago

Types of Anodizing Processes and Their Applications

Introduction: Anodizing can be performed in different ways based on the metal’s purpose and usage

Explore the different types of anodizing—Type I, II, and III—and learn how each process is used in aerospace, architecture, electronics, and more.

10 months ago

Anodizing and Its Benefits in Industry

IntroductionAnodizing is an electrochemical process that enhances the surface properties of metals, particularly aluminum, by creating a durable and corrosion-resistant oxide layer

iscover how anodizing improves corrosion resistance, aesthetics, and hardness of metals—especially aluminum—in key industries like aerospace, automotive, and electronics

English

English

العربية

العربية