home > Blogs

🟧 Introduction

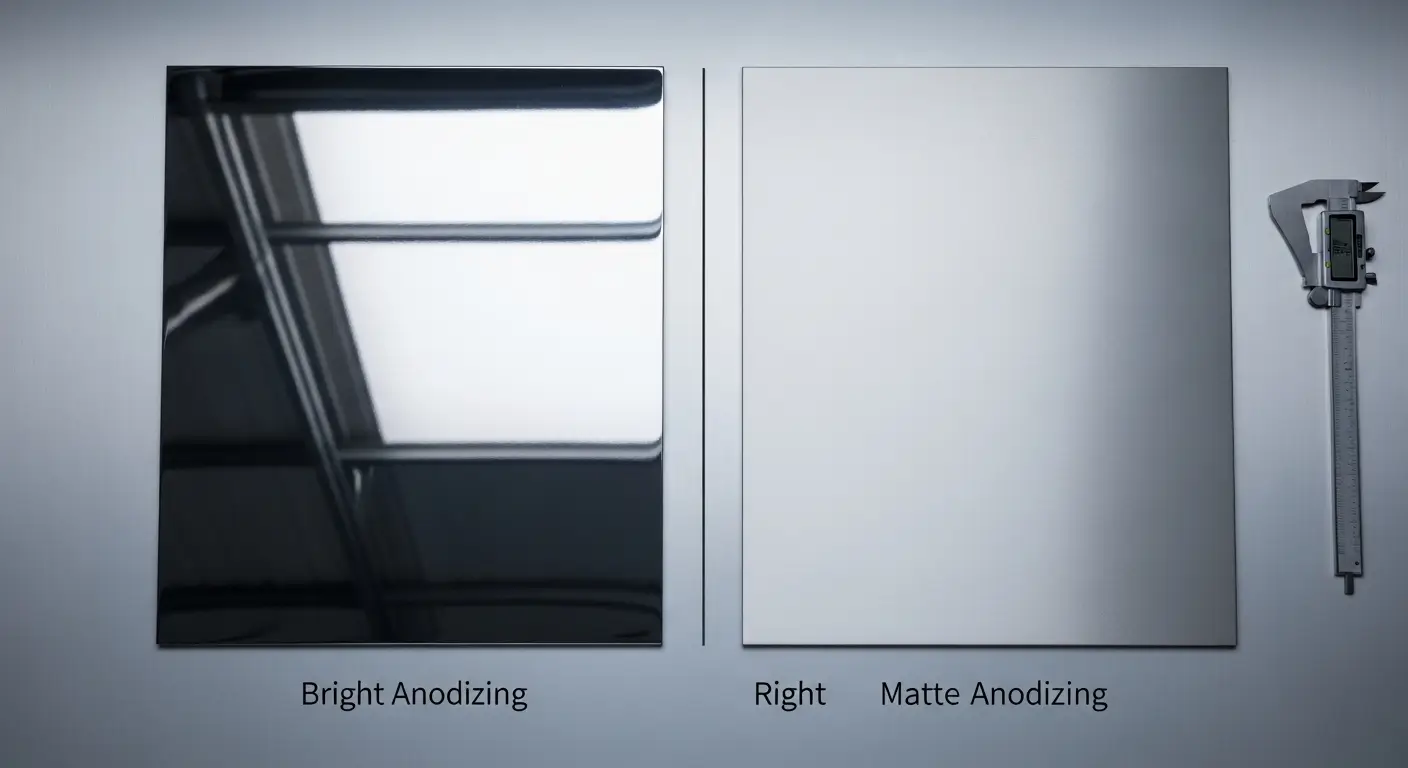

Anodizing defines the final look and performance of aluminum surfaces.

But one frequent question is: Should I choose a bright or a matte finish?

The answer depends on functionality, design intent, and lighting conditions.

🔹 Bright Anodizing

Bright anodizing follows chemical or mechanical polishing before the anodizing process.

It creates a clear oxide layer that enhances the natural reflectivity of aluminum, giving it a mirror-like brilliance.

Advantages:

Disadvantages:

Common Uses:

🔹 Matte Anodizing

Matte anodizing is achieved through sanding or etching before anodizing to diffuse reflections.

It results in a soft, tactile surface with a subtle, modern aesthetic.

Advantages:

Disadvantages:

Common Uses:

🔹 Quick Comparison

🔹 Quick Comparison Between Bright and Matte Anodizing:

1. Appearance:

Bright anodizing reflects light vividly, giving aluminum a glossy, mirror-like shine.

Matte anodizing offers a soft, non-reflective surface with a calm, premium look.

2. Texture:

The bright finish feels ultra-smooth and polished, while the matte surface is silky and velvety to the touch.

3. Scratch Resistance:

Bright anodizing has moderate resistance to scratches, while matte anodizing hides marks better and is more durable.

4. Ideal Applications:

Bright anodizing suits decorative items, handles, and appliance trims.

Matte anodizing is perfect for building facades, metal furniture, and industrial components.

5. Common Colors:

Bright finishes usually come in silver, gold, or champagne.

Matte finishes are typically silver, gray, or black.

🟩 Conclusion

Choosing between bright and matte anodizing depends on your design vision and performance needs.

At Golden East for Trade & Industry, we deliver both finishes to ISO 7599 standards, combining aesthetics with durability.

✨ Golden East – Precision in Every Detail.